+86-0769-85704089

What is UL halogen-free electronic wire? -- Analysis of the Core Characteristics of Environmentally Friendly Cables

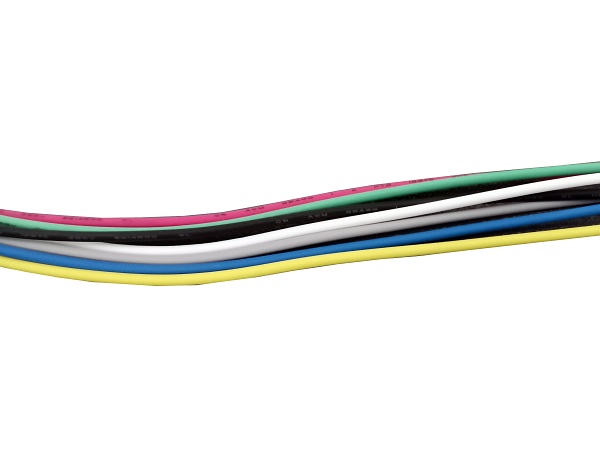

UL Halogen-Free electronic Wire (Halogen-Free Wire) is an environmentally friendly wire that meets the UL (Underwriters Laboratories of the United States) certification standards. Its core feature is that it does not contain halogens (such as chlorine, bromine, fluorine, iodine, etc.), and it is low smoke, non-toxic and flame-retardant when burning. It is widely used in fields with high requirements for safety and environmental protection. Such as data centers, new energy vehicles, medical equipment, etc.

I. Definition and Core Characteristics of Halogen-free Electronic Wires

What is "halogen-free"?

Traditional wires (such as PVC wires) : contain halogens (such as chlorine), and when burned, they release toxic gases (such as dioxins) and thick smoke, which are harmful to human health and the environment.

Halogen-free electronic wire

Halogen content ≤ 900ppm (conforming to IEC 60754-1 standard).

When burning, it only releases a small amount of non-toxic gases (mainly composed of water vapor and carbon dioxide).

2. Core characteristics of halogen-free electronic wires

Feature Description

Low Smoke (LS) has an extremely low smoke density during combustion (conforming to the IEC 61034 standard).

Zero Halogen does not contain halogens such as chlorine and bromine, reducing the release of toxic gases.

Flame Retardant has passed UL VW-1, IEC 60332 and other Flame Retardant tests.

Environmental protection (RoHS/REACH) complies with the EU RoHS and REACH regulations and contains no harmful substances.

Common high-temperature resistance grades: 80°C, 105°C, 125°C (more stable than PVC).

Ii. Materials and Structure of Halogen-free Electronic Wires

Conductor material

Oxygen-free copper (OFC) : Good electrical conductivity and strong oxidation resistance.

Tin-plated copper: Enhances corrosion resistance and is suitable for humid environments.

2. Insulating layer materials (Key difference)

Material type characteristics and applications

PVC (traditional wire) contains halogens and is toxic when burned in ordinary household appliances and low-end cables

PE (polyethylene) is halogen-free, but in the early stage of flammability, halogen-free wires need to be added with flame retardants

LSZH (Low Smoke Zero Halogen Polyolefin) is halogen-free, flame-retardant and low smoke for data centers, subways and medical equipment

TPE (Thermoplastic Elastomer) has good flexibility and is resistant to bending in robot cables and wearable devices

Iii. Certification Standards for Halogen-free Electronic Wires

1. International common standards

IEC 60754-1/2: Test the acidity of the gas during combustion (pH value ≥4.3, electrical conductivity ≤10μS/mm).

IEC 61034: Measurement of smoke density (transmittance ≥60%).

UL 1581: General Electronic Wire Testing Standard (including flame retardancy, aging, etc. tests).

UL 758 (AWM standard) : Certification for internal wiring of electronic devices.

2. Environmental protection regulations

RoHS (European Union) : Restricts harmful substances such as lead, cadmium and mercury.

REACH (European Union) : Controls high-risk chemical substances such as halogens.

CP65 (California, USA) : It is required to label potential carcinogens.

Iv. Application Fields of Halogen-free Electronic Wires

Data center & Communication equipment

Reason: To reduce toxic smoke during a fire and ensure the safety of personnel.

Standard: TIA-942 (Halogen-free wires are required for data center cabling).

2. New energy vehicles (High-voltage wiring harnesses

Reason: The battery pack needs to be flame-retardant and low-toxic in high-temperature environments.

Standard: ISO 6722 (Halogen-free Trend for Automotive Cables)

3. Medical equipment & Rail Transit

Reason: Enclosed Spaces need to avoid the risk of smoke suffocation.

Case: Special cables for subway carriages and operating room equipment.

4. Consumer electronics (USB cable, charger)

The reasons are: Apple's MFi certification and the EU's environmental regulations promoting halogen-free.

V. Comparison between Halogen-free Electronic Wires and Traditional PVC Wires

The comparison item is halogen-free electronic wire and traditional PVC wire

Halogen content ≤900ppm, chlorine content (15% - 30%)

Low toxicity (water +CO₂) and high toxicity (HCl+ dioxin)

The smoke density is extremely low (high light transmittance). Thick smoke (low light transmittance)

Excellent flame retardancy (UL VVW -1) General (flame retardants need to be added)

Environmental friendliness complies with RoHS/REACH and may contain lead/cadmium

The cost is relatively high (+20% to 50%) and low

Vi. Frequently Asked Questions (FAQ)

Q1: Are halogen-free electronic wires definitely flame retardant?

Not necessarily! Specific certifications (such as UL VW-1, IEC 60332) need to be checked. Some halogen-free materials (such as PE) are inherently flammable and require the addition of flame retardants (such as aluminium hydroxide).

Q2: How to distinguish genuine from fake halogen-free wires?

Check the certification: The UL certification number can be verified on the official website (such as E123456).

Combustion test: When genuine halogen-free wire burns, it has a small flame, no black smoke and white ashes.

Laboratory testing: Halogen content measurement (XRF spectrometer).

Q3: Why is halogen-free wire harder than PVC wire?

Halogen-free materials (such as LSZH) are filled with a large amount of flame retardants (aluminum hydroxide), resulting in a decrease in flexibility. Improvement direction: Use TPE-based halogen-free materials.

Vii. Future Trends

Higher temperature resistance: 150°C+ halogen-free materials (suitable for fast charging of electric vehicles).

Flexible halogen-free wire: Foldable devices drive the development of halogen-free TPE wires.

Recycled and environmentally friendly: Bio-based halogen-free materials (such as PLA modification).

Summary

UL halogen-free electronic wire is a cable solution that combines safety, environmental protection and high performance, especially suitable for scenarios with strict requirements for fire safety. When selecting a model, attention should be paid to the certification standards (UL/IEC), material types (LSZH/TPE), and temperature resistance grades to ensure long-term reliability.

Dongguan Futai Electronic Technology Co., Ltd. All Rights Reserved

Dongguan Futai Electronic Technology Co., Ltd. All Rights Reserved

Contact information

Mr. Li: +86-18688316819